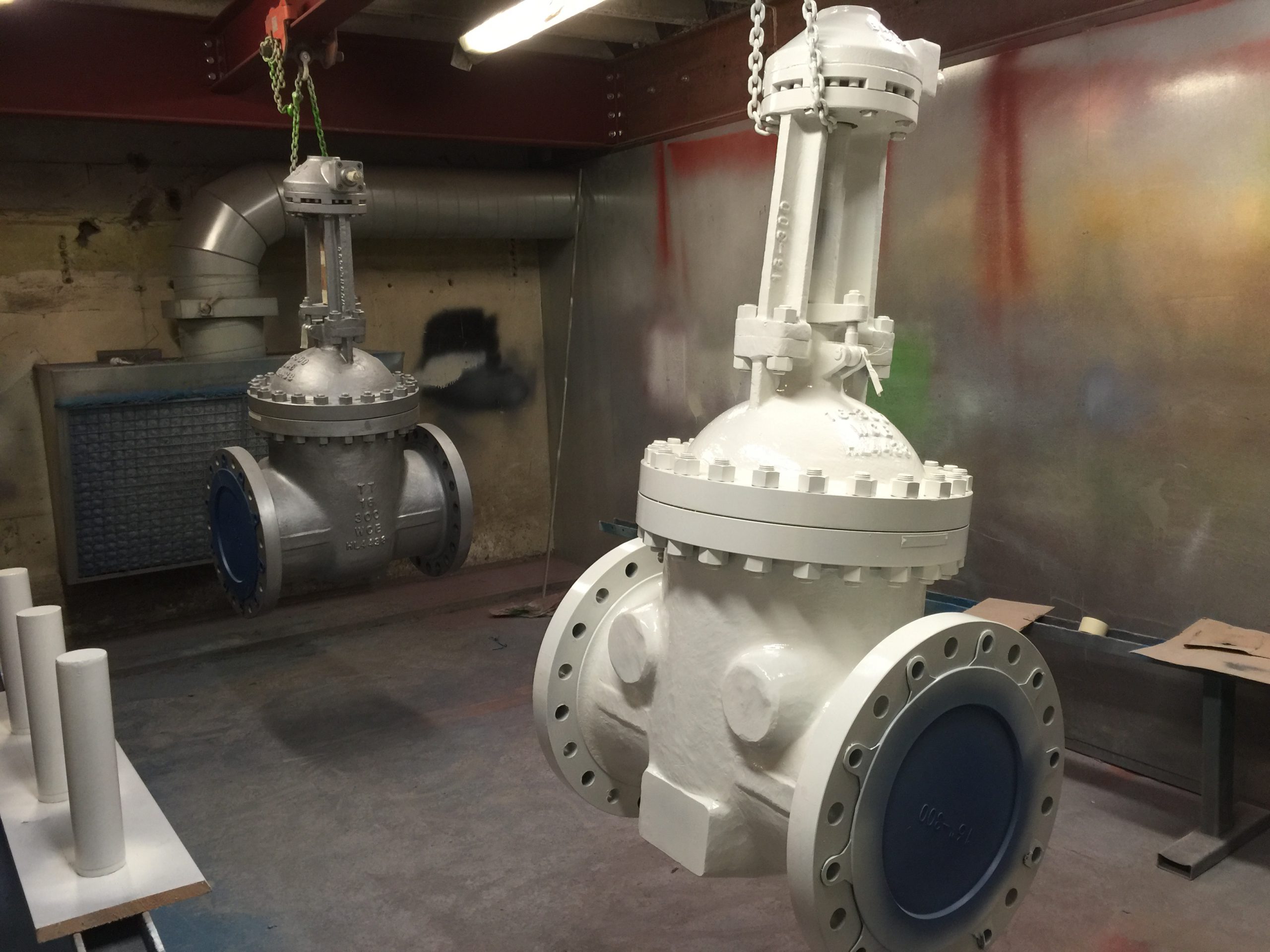

Painting

We have two spray painting booths which can accommodate for all variations of paint finish required, from a standard one pack primer to two pack marine coating systems.

Our painters are highly experienced in all types of coatings and achieve the high level of finish required.

We deal with most industrial paint manufacturers, but we can also work on a free issue paint basis if preferred. Both dry and wet paint film testing can be carried out to suit your requirements.

Shot-Blasting

Achieving a high-quality paint finish is all in the preparation.

Blasting in-house allows us to inspect the fabrication before it is painted to ensure that all the scale has been removed and that the paint has a good clean substrate to adhere to.

Our shot blasting bay capacity can cover some 14 metres in length x 3 metres wide x 2.6 metres high x 10 tonnes in weight. Using our standard cast iron grit, we can achieve a surface profile finish of between 40 and 70 microns, which allows us to conform to both Swedish Standards SA2 & SA2.5.

Our second bay capacity covers 6 metres in length x 3 metres wide x 2.6 metres high this is mainly used to shot blast our lighter sheet metal items where a softer grit is used.

In addition we carry out mobile site shot blasting services.

Dry Ice Blasting (Cryogenic Cleaning) can clean without surface erosion.

This cleaning process produces a dramatic saving in staff hours and the costs concerning hazardous chemical substances.

It will also eliminate the potential damage to machine parts while eliminating secondary waste streams.

Results in a clean, dry surface with no residue – Dry ice pellets sublimate upon impact with the surface to be cleaned, so the pellets convert directly from a solid to a vapour.

Ice Blasting can be performed on a range of machinery such as substations, tyre moulds, automotive chain gear, foundry areas, fire and smoke remediation.

Machinery is cleaned in situ so it can continue to be in operation during cleaning, keeping downtime to a minimum.

Dry ice blasting is safe around electrical components as this method is free from moisture, so there is no need to cover electrical components.